|

|

Insert Types

Powercoil Free Running Inserts provide strong permanent internal threads that resist heat and corrosion. Once fitted, their position is maintained by the action of radial pressure between their coils and the flanks of the tapped hole. This pressure exists because the free diameter of Powercoil Free Running Inserts is larger by a calculated amount than their installed diameter.

Powercoil Screw Locking (or prevailing torque) Inserts are of particular value in applications subject to the effects of cyclic vibration or impact. In addition to the benefits afforded by free running inserts, Powercoil Screw Locking Inserts offer the additional security of prevailing locking torque.

This is achieved by the action of one or more polygonal grip coils positioned within the insert's length, which exerts radial pressure on the male thread. Each grip coil on Powercoil Screw Locking Inserts consists of a number of tangential locking chords which protrude inside the minor diameter of the normal free running coils. As the male thread passes through these grip coils, the locking flats are displaced, exerting radial pressure or prevailing torque on the male thread. On removal of the male thread, the locking coils in Powercoil Screw Locking Inserts relax to their original form, permitting repeated assembly whilst retaining a measurable level of prevailing torque. Thread TypesPowercoil Screw Thread Inserts are available in all popular thread types:

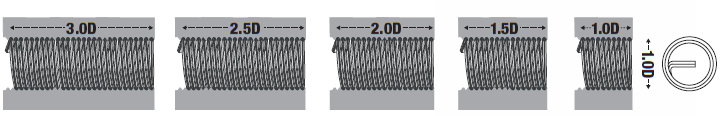

Insert LengthPowercoil Screw Thread Insert lengths are calculated in multiples of the nominal thread size, or diameter, of the insert. Five insert lengths (1D, 1.5D, 2D, 2.5D and 3D) are available for each thread size.

|

Powercoil Free Running Inserts

Powercoil Free Running Inserts